Wechat ID:WANGYUNHUA

Wechat ID:WANGYUNHUA

Wechat ID:WANGYUNHUA

Wechat ID:WANGYUNHUA

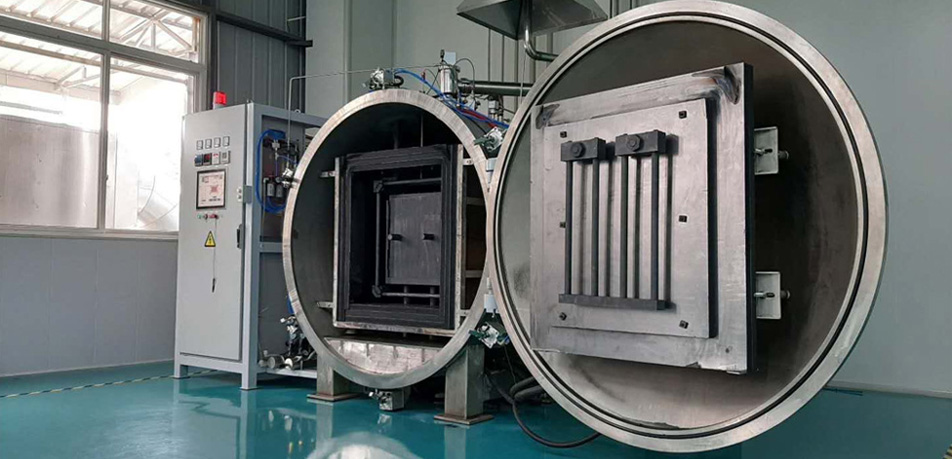

Suzhou Meiteng Furnace Industry Co., Ltd. (MT) was established in January 2013, and its core personnel are all former members of a large tungsten molybdenum product vacuum furnace business unit. We have a profound understanding of ultra-high temperature sintering. Our company specializes in producing ultra-high temperature sintering furnaces with temperatures up to 3000 ℃, which are used in new material industries such as tungsten based sintering, ceramic sintering, metallization, carbonization sintering, etc.

MT Mechanical and electrical engineers have an average of over 14 years of design experience MT Installation technicians have over 12 years of installation and maintenance experience

MT Our thermal field and other key components are all produced by ourselves to ensure that the company's technology is not leaked, and to guarantee quality and lifespan.

The domestic equipment malfunction will be responded to by phone within 2 hours, and the requesting party's phone cannot handle the malfunction on their own. They will arrive at the scene within 24-48 hours. The MT machine comes with a two-year warranty, with free maintenance in the first year (excluding non-human damage) and cost maintenance in the second year. MT thermal field technology holds a high position in China, ensuring the high-temperature durability and ultra-low overall cost of the thermal field.

Ultra high temperature sintering furnace is a device that can sinter materials at higher temperatures. The following is a detailed introduction: 1. Working principle Resistance heating: Using current to generate heat through a conductor (such as a graphite heating element), following Joule's law, which states that heat is proportional to the square of the current, the resistance of the c

A single crystal growth furnace is an equipment used for growing single crystal materials. The following will provide a detailed introduction from the dimensions of its working principle, structural composition, and application fields: 1. Working principle Czochralski method: Place polycrystalline material into a quartz crucible and heat it with a graphite heater to melt it. Fix the seed

A single crystal growth furnace is an equipment used for growing single crystals, which plays a crucial role in various fields such as semiconductors, optics, electronics, etc. It mainly includes the following aspects: 1. Preparation of semiconductor materials: In the semiconductor industry, single crystal silicon is a key material for manufacturing integrated circuit chips. By correctly controll

The single crystal growth furnace has the following characteristics: 1. Proper control aspect Correct temperature: able to control the temperature within a very accurate range, for example, when growing silicon single crystals by direct pull method, the polycrystalline silicon raw material in the quartz crucible should be heated to above 1450 ℃ and kept stable. The accuracy of temperature

The ultra-high temperature sintering furnace has the following characteristics: 1. High temperature characteristics Ultra high temperature range: The most significant feature of ultra-high temperature sintering furnaces is the ability to provide a high temperature environment, generally reaching above 1800 ℃, and even some excellent equipment can exceed 3000 ℃. For example, sintering furn

Suzhou Meiteng Furnace Industry Co., Ltd. (MT) was established in January 2013, and its core personnel are all former members of a large tungsten molybdenum product vacuum furnace business unit. We have a profound understanding of ultra-high temperature sintering. Our company specializes in producing ultra-high temperature sintering furnaces with temperatures up to 3000 ℃, which are used in new material industries such as tungsten based sintering, ceramic sintering, metallization, carbonization sintering, etc. Our company is currently recruiting agents and partners from various regions. Welcome to come and discuss cooperation methods. Concept and Value MT cares about every employee, and employees are our foundation. The diligence, practicality, sincerity, and innovative thinking of MT employees are the foundation of enterprise development. The purpose of MT is to retain people, use good people, and give every employee a sense of home, a goal to strive for, and more dreams. MT makes good use of every resource to make our products more valuable and competitive. Technical situation MT mechanical and electrical engineers have an average of over 14 years of design experience. MT installation technicians have over 12 years of installation and maintenance experience. Our thermal field and other key components are all produced by ourselves to ensure that the company's technology is not leaked, and to guarantee quality and lifespan. Ensure quality The domestic equipment malfunction will be responded to by phone within 2 hours, and the requesting party's phone cannot handle the malfunction on their own. They will arrive at the scene within 24-48 hours. MT has a two-year warranty for the entire machine, with free maintenance in the first year (excluding non-human damage) and cost maintenance in the second year. MT thermal field technology holds a high position in China, ensuring the high-temperature durability and ultra-low overall cost of the thermal field.